Hydrogel Reinforrcement

This project focuses on the development of a novel class of hybrid reinforced grafts in order to provide soft tissue implants with additional mechanical stability and flexibility. These hybrid grafts are composed of a hydrogel matrix that allows the proliferation of cells and of a titanium reinforcement to provide with additional stiffness.

Most medical implants are nowadays manufactured using biocompatible metals such as titanium. Titanium can also be ‘3D printed’ by means of selective laser melting (SLM). This project focuses on the design and analysis of titanium samples which are designed to be flexible in specific directions and to resist compression in others.

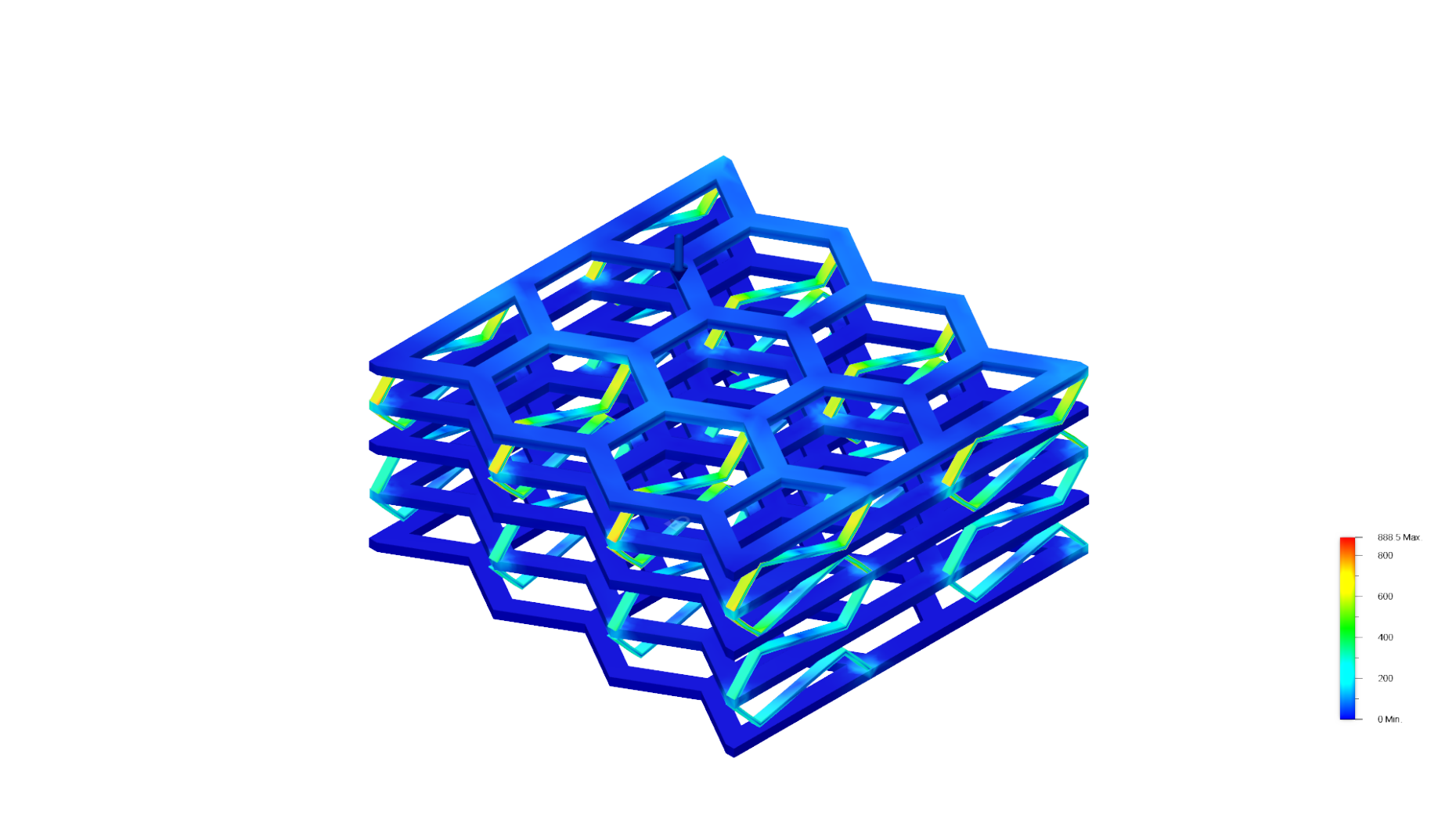

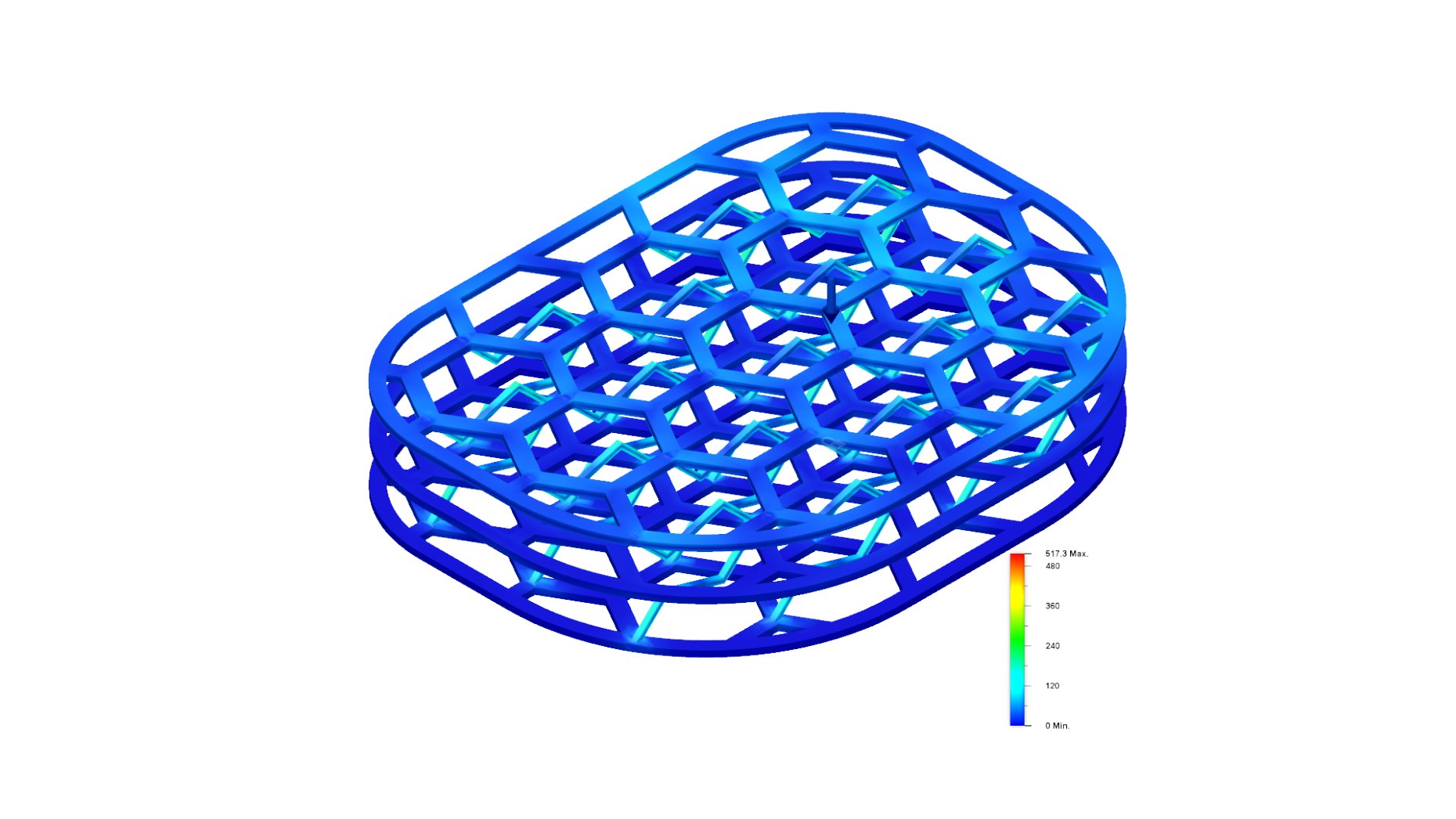

Finite element analysis (FEA) is used to predict and program deformation patterns in our constructs:

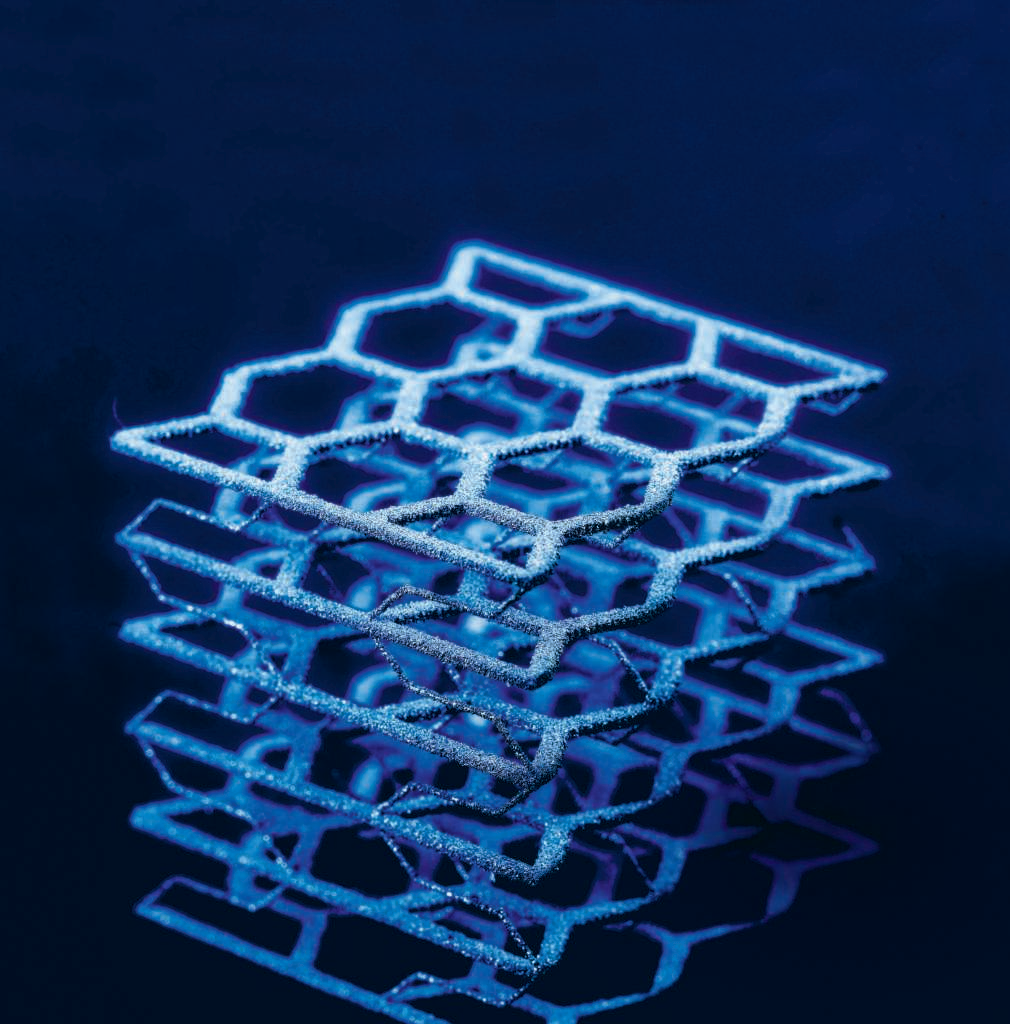

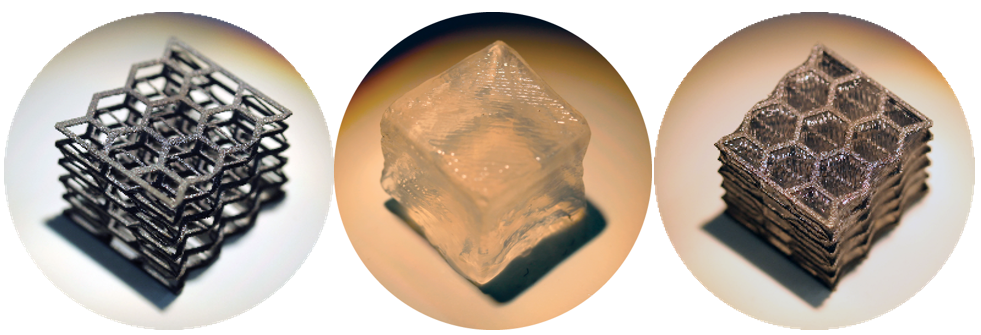

Parts are then SLM manufactured in a collaboration with the advanced materials processing laboratory at EMPA and are embedded in hydrogels:

Figure 3: Left: Titanium lattice produced using SLM. Center: 2% w/v Alginate cube. Right: Hybrid Ti+Alginate construct after embedding.

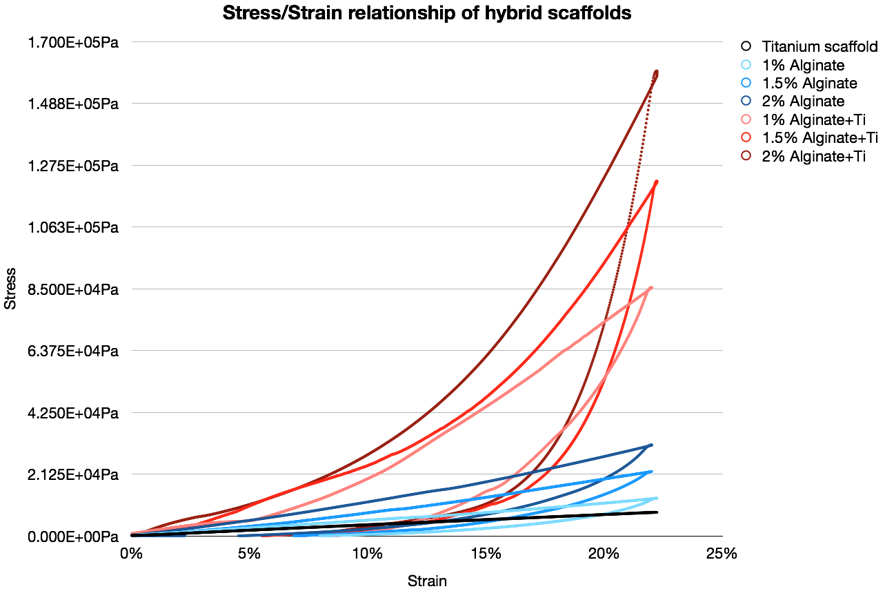

The mechanical properties of the titanium samples, hydrogels and hybrid construct are then analyzed by means of compression testing and show a combined viscoelastic response together with an increased stiffness with respect to the different components tested individually.

Figure 4: Stress/strain relationship of hybrid titanium alginate constructs under 22% strain at different alginate concentrations. A linear relationship of the titanium scaffold alone can be noticed (black line). Combining the alginate with the titanium scaffolds drastically increases the stress/strain relationship allowing the construct to sustain much higher loads.

REFERENCES:

1Caló, E., Khutoryanskiy, V. V. (2015). Biomedical applications of hydrogels: A review of patents and commercial products. European Polymer Journal, 65:252-267.

2J. An, S. Leeuwenburgh, J. Wolke, J. Jansen, 4 - Mineralization processes in hard tissue: Bone, Biomineralization and Biomaterials, 2016, Pages 129-146

This project is in a collaboration with the advanced materials processing laboratory at EMPA

This project has been funded by the GEBERT RÜF STIFTUNG

Contact

No database information available