MagnetoPrint

Tissue engineering is a rapidly growing field with significant potential for repairing damaged organs and improving drug testing methods. One of the primary challenges in tissue engineering is achieving biomimicry, where engineered tissues closely emulate their natural counterparts in terms of structure, function, and mechanical properties. This requires replicating the extracellular matrix (ECM) found in native tissues, which offers mechanical support, biochemical cues, and a scaffold for cell adhesion, playing a pivotal role in tissue development and maturation. Traditional static tissue culture methods have limitations in mimicking the dynamic and mechanically active environments that tissues encounter in the body. Especially for musculoskeletal tissues, maturation under dynamic loading conditions promotes cell proliferation and anisotropic matrix deposition which is important for biomimicry.

In the realm of tissue engineering, traditional mechanical contact-based approaches have played a significant role in providing the dynamic loading cues to engineered tissues. However, these methods are not without their limitations. One of the primary drawbacks is the challenge of maintaining sterility during direct mechanical contact with the cultured tissues, which can introduce contamination risks and complicate long-term cultivation. Furthermore, mechanical contact-based methods often offer limited control over the directionality and magnitude of the forces applied to the tissues, which can hinder the precise manipulation necessary for achieving biomimicry and promoting optimal tissue maturation.

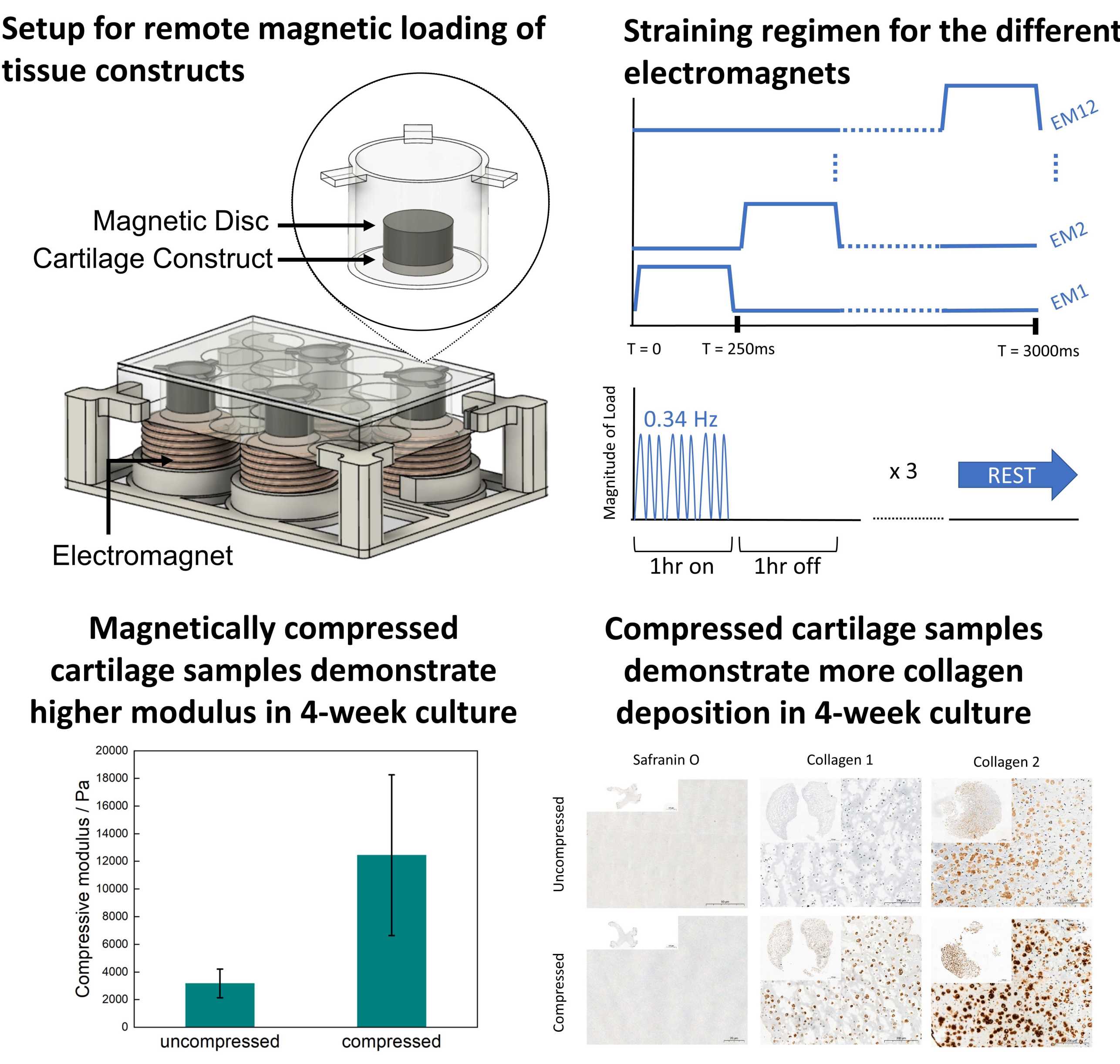

To address this challenge, this project aimed at developing a new MagnetoPrint system which allows integration of the electromagnetic straining apparatus within the biofabricated tissues to facilitate remote loading and enhancing maturation of engineered tissues. In the system engineered during the course of this project, the electromagnetic forces can be controlled around the tissues, which can induce mechanical strain and deformation in cultured tissues. This closely mimics the dynamic conditions experienced by natural tissues during development and daily activities. In the scope of the project, systems for cartilage have been developed, where both compressive and shear forces can be generated by changing the magnetic domain orientations within the electromagnetic straining system placed over the biofabricated cell-laden constructs. In short-term maturation over 3 weeks (long-term culture experiments are ongoing), the constructs demonstrated enhanced cartilage tissue maturation under dynamic loading compared to the constructs grown in static conditions. This research is currently still ongoing, where long-term maturation of cartilage is being explored and also the system is being adapted to other musculoskeletal tissues such as muscle and tendons.

Contact

Gewebetechnol. und Biofabrikation

Otto-Stern-Weg 7

8093

Zürich

Switzerland